EX-Technology

- Company Introduction

- Products

- Download Center

- News

- Support

PRODUCTS

Provide the best machine vision solution based on the cutting-edge technologyIndustrial Camera

Unlike general DSLR cameras, industrial cameras used in machine vision do not have the ability to store images immediately, so they have to be applied in conjunction with image grabber and illumination and lenses accordingly, also these cameras are used various application such as

In the Machine Vision applications, image processing technology for accurate measurement is one of the key areas, and industrial cameras perform better than digital cameras used for typical photography and should be applicable to a variety of environments.

Furthermore, there are many cameras according to sensor types and usage those are area, line, TDI, Polarization, Spectrometer, 3D & Smart camera.

Because image defect detection and measurement requires accurate and fast image extraction, the image quality of the industrial camera is superior to that of the 'normal' camera, and the industrial camera is connected to the computer via various application interfaces and outputs images using input/output cables.

Industrial cameras include with GigE Vision, Camera Link, USB Vision, Analog Vision, Coax Press, etc. Depending on the interface, images are transmitted to the PC through various interfaces to measure, detect defects, etc.

| Interface |

GigE(POE)

GigE(POE)

|

Camera Link

Camera Link

|

USB

USB

|

CoaXPress

CoaXPress

|

|---|---|---|---|---|

| Transfer Speed | 1000 Mb/s | Max. 3.6 Gb/s | 5 Gb/s | Max. 12.5Gb/s |

| Cable Length | 100m | 10m | 3m | 100m |

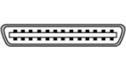

| Connector | RJ45 | 26pin | USB | RG59/RG6/RG11 |

| Image Grabber | No Need | Need | Option | Option |

| Power | No Need | Need | Option | Option |